Have you ever wondered what is the solar panel carbon footprint?

Solar power is becoming a leading renewable energy source thanks to larger energy capabilities and a government push to invest in green energy. The U.S. Energy Information Administration (EIA) estimates that solar energy could be generating 286 billion kilowatt hours (kWh) by 2025.

However, while solar power is green energy, manufacturing solar panels does create a carbon footprint. The carbon footprint is the total amount of greenhouse gasses, carbon dioxide, and methane created when something acts upon the environment.

Unlike other energy generation methods, solar’s contribution outweighs its carbon footprint.

What is the Carbon Footprint of Manufacturing a Solar Panel?

According to the International Panel on Climate Change (IPCC), 1 kWh of electricity produced by a solar panel produces 41 grams of CO2-equivalents.

That number may seem high without the proper context. However, compared to other ways of generating electricity, such as burning fossil fuels, this is not the case. More precisely, 41 g/kWh places solar energy among some of the lowest emission numbers. Only hydroelectric, nuclear, and wind power possess a lower carbon footprint than solar power.

“The number assigned for any solar carbon footprint may not be exact as it considers several factors in its calculations..“

The solar carbon footprint is still higher than many in the industry believe it should be. Many processes can be optimized and made more energy-efficient to reduce the carbon footprint at each stage.

These small changes can cause a cumulative effect and a smaller solar footprint will result.

Considerations When Calculating a Solar Panel Carbon Footprint

When calculating 41 g/kWh, the IPCC considers a solar panel’s entire lifecycle. This includes manufacturing, transportation and distribution, installation, and disposal at the end of its life.

The number assigned for any solar carbon footprint may not be exact as it considers several factors in its calculations.

Types of Solar Panels

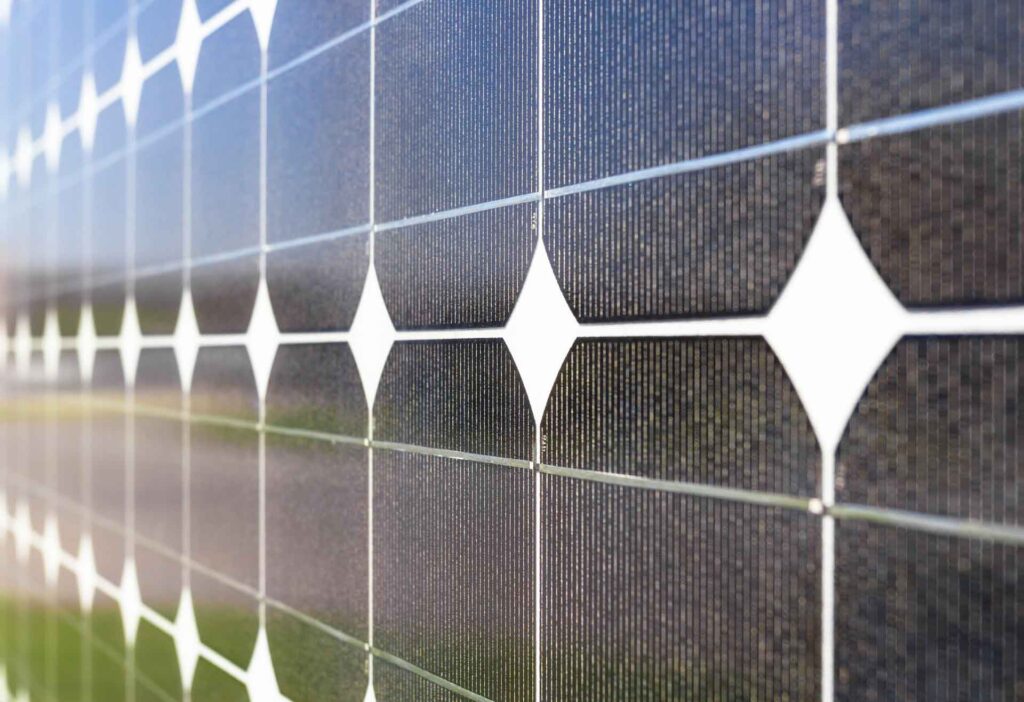

When assessing the solar panel’s carbon footprint, it’s also important to remember that there are two types of solar panels: monocrystalline and polycrystalline.

- Monocrystalline solar panels are the most popular panel type. When manufacturing a monocrystalline solar panel, silicon is molded, cut into pieces, and attached to the solar panel.

- Polycrystalline, which is a more labor and energy-intensive process, requires melting silicon crystals together to create the multiple layers of the solar panel.

Each type produces a different carbon footprint, which this calculation averages together.

Data Transparency

The data regarding parts of the solar energy supply chain is easily accessible. However, some of the data needed to make this calculation need estimation because of a lack of transparency. This calculation includes the mining and refining of raw materials. In addition, it also includes the required manufacturing components for creating a finished solar panel suitable for selling.

Groups like the Coalition of Materials Emissions Transparency (COMET) are working to accelerate the decarbonization of energy sources by establishing carbon transparency from mining to the finished product. They also want to make carbon emission data available to end consumers, not just groups like IPCC.

Data transparency would allow consumers to vote with their money and purchase products from organizations that prioritize lower carbon emissions. COMET aims to create carbon-free buildings, electricity, and transportation in the U.S.

Solar Panel vs. Other Energy Sources

In 2014, the IPCC calculated the gram of carbon per kilowatt hour values of life cycle CO2-equivalent emissions for solar panels and several other renewable and non-renewable energy sources.

Rooftop solar panels, as they were manufactured and distributed in 2014, offered a lower carbon footprint than fossil fuels and a comparable amount compared to other renewable energy sources. Gas produces 490 g/kWh, over ten times the carbon emissions solar panels produce. The burning of coal is twenty times that at 820 g/kWh.

Chart: 2014 Median Values according to the IPCC

Life Cycle Analysis of a Solar Panel Footprint

One method of assessing the environmental impact of a solar panel begins by evaluating and calculating the carbon emissions. Of course, this applies to all carbon emissions it produces during all stages of its lifecycle.

It begins with manufacturing and sourcing raw materials, which historically have always required energy and non-renewable resources.

However, technology improves and the public and advocacy groups demand greener processes, sourcing, and mining. Consequently, raw materials have become more environmentally conscious. Manufacturers are using less and recycling more, reducing emissions using biofuel, and implementing renewable energy sources where possible.

Manufacturing

This stage produces the most carbon emissions. It includes obtaining raw materials through energy-intensive operations like mining, refining them, and constructing components for the solar panels.

Silicon and glass are needed for solar cells. Lithium is required for the battery. Fine metals and trace minerals like copper, silver, tellurium, and indium help further compose each panel.

Transportation and Distribution

Transportation includes shipping raw materials to assembly stations and distributing finished panels to the market, both creating carbon emissions.

Manufacturers have been experimenting with shorter transportation routes and methods, such as using biofuel trucks and combined shipping with other products rather than driving for just one product.

Installation

Installation crews must use transportation to get to installation sites, but otherwise, this stage creates very few carbon emissions. As the industry improves, human crews have switched to renewable energy sources when necessary to help further offset their footprint.

Usage and Output

Like wind power, solar panels don’t produce any direct carbon emissions. As a renewable energy source, it is estimated that after approximately three years of use, solar panels begin to create enough energy to offset their initial carbon output.

With a lifespan of 30-40 years, this means that solar panels produce greatly outweigh the negative impact necessary for their manufacturing.

Disposal

Like the recent rise in electronics manufacturing, solar panel manufacturers are working to improve the end-of-life of their products. The industry is placing a heavier emphasis on the proper disposal of panel components to lessen environmental impact. This includes safe disposal of elements that can’t be reused and recycling those that can.

Reclaiming metals and minerals and recycling materials can help offset emissions and protect non-renewable resources by reducing the need to mine new materials and improving mining conditions and processes.

Advancements in Solar Energy

Each stage of the solar panel lifecycle offers room for improvement and the refinement of processes to reduce the solar carbon footprint. Every day, advancements in technology help in producing energy with a smaller carbon footprint.

“As the industry is expanding rapidly, the need for skilled workers is growing.“

The most common advancements include changes in materials at the manufacturing level to increase solar cell efficiency and reduce environmental impact. Smarter energy use and advancements in techniques are also being implemented at every stage during manufacturing and distribution.

New Materials

New photovoltaic materials that can replace silicon and glass have been developed, although they are still in testing and not yet ready for use in solar panel production.

If they operate as expected, these materials take less energy to produce, can absorb more light, and successfully conduct electricity more efficiently than traditional materials. One panel could hypothetically replace many traditional panels for the same carbon footprint.

Minerals like Perovskite, a type of calcium titanium oxide, also have physical and chemical properties that could make them a good option for solar cells. While Perovskite is mainly found in Russia, there are also deposits of Perovskite varieties in Italy, Switzerland, and Arkansas.

Energy Storage

Solar cell energy storage is also improving. Lithium-ion and flow batteries are being developed that have a longer lifespan than traditional lithium and hold a charge better for longer. These batteries will be able to be recycled more often and need to be replaced less frequently.

Policies and Tax Credits

Federal and state policies constantly adapt and improve to encourage consumers to use renewable energy and reduce manufacturers’ environmental impact.

The Solar Investment Tax Credit (ITC) was created to encourage businesses and consumers to include solar panels. The cost of solar technology was offset by a credit given in proportion to the number of solar panels installed.

Governments are also encouraging the growth of the solar energy sector by implementing tax credits that focus on increasing the number of installed solar panels. This has led the industry to work towards even lower emissions, search for more efficient ways of manufacturing solar panels, and to create more solar energy jobs.

Solar Energy Jobs

With the rise of information about the benefits of renewable energy, consumers are becoming more interested in solar energy, and in turn, homebuilders are adding it to their builds accordingly.

This increase has also led to the creation of more jobs. As of 2023, the growth of the solar energy sector has boosted job creation to over 270,000 workers, an increase of almost 6% since 2022.

The industry is expanding, and the need for skilled workers, such as solar engineers and technicians, has grown. However, manufacturing, installation, and maintenance jobs have also been added to meet the demand. Many of these solar energy jobs, which have been created in local communities, also offer higher salaries than similar jobs in other energy sectors.

Final Thoughts

While calculating a solar power carbon footprint is complex, and data transparency needs to be improved to obtain a more accurate reading, solar energy in the United States is already providing Americans with a reliable and renewable energy alternative.

While there is a solar panel footprint, solar panel manufacturing is a sustainable way to provide green energy. With a lower environmental impact than fossil fuels and a comparable carbon footprint to other renewable sources, the industry’s advancements are improving energy technology and creating jobs every day.